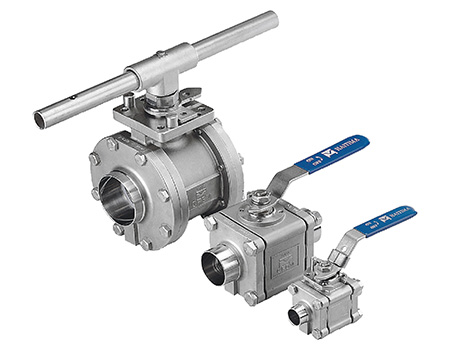

Bio Valve and Sanitary Components

2013KB-BPE / 2013KC-BPE

Pharmaceutical, Food, High Vacuum, BPE Fitting

The HAITIMA clean sanitary ball valve is designed to the highest standards to comply with ASME BPE, ASME B16.34 and API598. It is designed with a full “tube bore”, where the ID of the valve equals the ID of the tube and thus ensuring maximum flow capcity with minimum pressure drop across the valve, The full “tube ID” also ensures clean ability and drainability as mandated by ASME BPE. Extended weld ends as per ASME BPE with sulphur Control (0.005 0.017%) for orbital welding.

2013KB

FEATURES

- Tube end, 1/2″~4″ (DN15~DN100)

- Body W.P.: 1000 WOG (PN63)

- Tube End W.P.: 200 WOG

- W.T.: -20°C~200°C (-4°F~392°F)

- Investment casting

- Blow-out proof stem

- Live-loading design

- Anti-static device (option)

- Cavity filled seats

- Locking device

- ISO 5211 Mounting pad

2013KB-BPE:

- Tube end castings have low sulphur content of 0.005-0.017%

- Extended tube end (ETO)

2013KC

FEATURES

- Clamp end, 1/2″~4″ (DN15~DN100)

- Body W.P.: 1000 WOG (PN63)

- Clamp End W.P.: 200 WOG

- W.T.: -20°C~200°C (-4°F~392°F)

- Investment casting

- Blow-out proof stem

- Live-loading design

- Anti-static device (option)

- Cavity filled seats

- Locking device

- ISO 5211 Mounting pad

2013KC-BPE:

- Clamp end castings have low sulphur content of 0.005-0.017%